Many people design 3D parts for art, beauty or decoration. I found that plastic injection molding do a better job. My primary 3D printing is for engineering purpose. So I am more concern about the dimension accuracy and strength of objects. I like to use PLA and ABS if I really need to.

Did you ever had the frustration where by you took something from thingiverse and JUST PRINT IT.

Oh my god, it print nicely but it does not fit.

First, you need to know your printer print out accuracy. It applied to external dimension ( overall length, width and height) and internal like holes, slot, fillet etc.

If you design a hinge , you need to know how much offset it will really print. Let take this as an example. If your thickness of the yellow colour hinge is wrong, you can never fit in. Lets say the space between 2 blue hinge is 4 mm. so you thickness cannot be 4mm. if you know you print out will be about 4.1mm, then you can safely set you width to be 3.7 to 3.5. Always reduce your thickness by about 0.2 mm or more.

Next the hole. You might ask HOW BIG SHOULD THE HOLE SIZE BE ?

This guidelines is exactly the same as normal drilling. If you screw is 3mm, you hole should be 3.5 mm. Unless you can get a very accurate printout, but remember, beside the hole size, your position will be offset. I do not like to do too much post procession like drilling to enlarge the hole, because you will cause the hole structure to weaken. I find that some Thingiverse user draw hole which is EXACTLY the same size as screw....

Next adding fillet to the parts. what is a fillet. fillet has 2 used. one is for strength, one is for smoothness.

to be continued ....

This is a blog for my 3d printer built and arduino examples. I am a lecturer in Robotics and I like to share some of what I had done and what my students had done. Also I will share how to design a good 3D printable object.

Monday, 4 April 2016

How to print a good 3D print out ...

Let me share with everyone how to get a good print out.

First since 3D printer is a precision equipment, if your components are not precise, you will never get a good printout for a reasonable time. eg, use of threaded rod may not be ideal for a long time.

Let's assume, you have a structurally stable and good print head or extruder.

First in order to print well, look at the first layer. If it print well, you will more likely to get a good printout. If it does not, the structure will move and you will a pile of rubbish.. what do I mean by a good first layer. Assume that you had calibrated the flow rate and you do not get something like this....

1) Print bed slanted - You will see one side is crushed and the other side does not stick well.

Remedy : make the bed flat or it could be your print head is slanted.

2) Print head too high - the print out just does not stick to surface .

Remedy : I prefer to adjust the Z offset in my slicer program. it is easier because your are talking about probably 0.1 to 0.4 mm. Adjust your stop switch will be tough.

3) print head too low - will cause excessive adhesion to surface. Filament will get compressed on the surface and if you see carefully, you will see that it is very flat and enjoy your hard time getting the pieces out of the heated bed. I prefer to adjust this by the Z-offset also. It is easier.

This print out is good. A little more will crush and compressed the print out.

Next let's talk about the various type of surface to print on.

1) kapton tape: My experience is, it is not very sticky and in the surface is too little , the printout will dropout. So I will definitely put a raft layer as a interface layer. I use it on the Felix printer.

2) Uhu Glue on glass - The prusa I have is using UHu glue on glass. It sticks really well. even when the base is small. Usually I apply 1 time, I can use it for many print.

3) Blue painter tape: the adhesion is pretty strong also, but sometime, it just come out with the printout. So I find it quite a trouble to reapply the blue tape.

I will edit with more pictures when I gather them ...

First since 3D printer is a precision equipment, if your components are not precise, you will never get a good printout for a reasonable time. eg, use of threaded rod may not be ideal for a long time.

Let's assume, you have a structurally stable and good print head or extruder.

First in order to print well, look at the first layer. If it print well, you will more likely to get a good printout. If it does not, the structure will move and you will a pile of rubbish.. what do I mean by a good first layer. Assume that you had calibrated the flow rate and you do not get something like this....

1) Print bed slanted - You will see one side is crushed and the other side does not stick well.

Remedy : make the bed flat or it could be your print head is slanted.

2) Print head too high - the print out just does not stick to surface .

Remedy : I prefer to adjust the Z offset in my slicer program. it is easier because your are talking about probably 0.1 to 0.4 mm. Adjust your stop switch will be tough.

3) print head too low - will cause excessive adhesion to surface. Filament will get compressed on the surface and if you see carefully, you will see that it is very flat and enjoy your hard time getting the pieces out of the heated bed. I prefer to adjust this by the Z-offset also. It is easier.

This print out is good. A little more will crush and compressed the print out.

Next let's talk about the various type of surface to print on.

1) kapton tape: My experience is, it is not very sticky and in the surface is too little , the printout will dropout. So I will definitely put a raft layer as a interface layer. I use it on the Felix printer.

2) Uhu Glue on glass - The prusa I have is using UHu glue on glass. It sticks really well. even when the base is small. Usually I apply 1 time, I can use it for many print.

3) Blue painter tape: the adhesion is pretty strong also, but sometime, it just come out with the printout. So I find it quite a trouble to reapply the blue tape.

I will edit with more pictures when I gather them ...

Tuesday, 22 March 2016

The 3D printers that I used

I am very fortunate that I used many of the 3D printers due to my work. Lets just talk about reasonable one. And forget about those that cannot make it.

Felix - The program, print is very good at the price of the printer. But I find that it does not stick to surface of the heated bed well. often need to add additional perimeters to stablelize it. Sometimes, half way through, the object just lift up and drop ...dead... Other than that it is fine, especially when I print honey comb structure.

Next , I used Uprint. This is a more professional machine than the conventional Reprap family. It used propietry filament and support material. They sell in a carton of 7 sets. Costing about USD 1 K per box. The filament is ABS. The support material is soluble in acid. Print out is very hard, professional. But cost wise, it is higher. The support material is actually not so hard to take out, even if you are using simple tools like penknife and screw driver. Unless REPRAP machine, the support material is the same and hence hard to take out. Even if u can, it take a long time to clean up.

The printout is super smooth. It actually flatten every layers and make a smooth surface.

Felix - The program, print is very good at the price of the printer. But I find that it does not stick to surface of the heated bed well. often need to add additional perimeters to stablelize it. Sometimes, half way through, the object just lift up and drop ...dead... Other than that it is fine, especially when I print honey comb structure.

Next , I used Uprint. This is a more professional machine than the conventional Reprap family. It used propietry filament and support material. They sell in a carton of 7 sets. Costing about USD 1 K per box. The filament is ABS. The support material is soluble in acid. Print out is very hard, professional. But cost wise, it is higher. The support material is actually not so hard to take out, even if you are using simple tools like penknife and screw driver. Unless REPRAP machine, the support material is the same and hence hard to take out. Even if u can, it take a long time to clean up.

Also with this machine, I can tilt or adjust my printing to suit the force exerted on the layers. As we know, one of the weakness of 3D printing is due to the layers. If you exert a force parallel the layers, it might give way. So for Uprint, we can tilt the angles of the print out till the forces are not parallel to layering. Of course at the expense of the support material.

Next, we have OBjet.

OBjet is very expensive.The material is also very expensive. I would have though that this machine can print out molding quality. But I discover I was wrong. Conventional 3D printer including Uprint uses material that is quite brittle and not soft like injection molded plastic. So under pressure, the printout might crack or give up. With OBjet, I thought it will be much better. Later I realised that this is not the case. It still crack. Although the material is better the PLA or ABS. The printout is super smooth. It actually flatten every layers and make a smooth surface.

Another problem with OBjet is, you need to go through washing to clean the parts, as the parts is still wet after printing. Cleaning will take a you while to do it. You can see it is very well protected, the material could be a bit toxic. The material is VERY expensive.

Comparing J-head hotends

I had bought quite a few hotends. I bought

1) J-head , Aluminium nozzle , Plastic body

2) J-head with aluminium heat sink and brass nozzle.

3) Mk7Direct extruder

4) E3D Hotends.

Also , I had many sizes of nozzles. 0.2 to 0.5 And in the end, I prefer to use 0.4.

Let's talk about this type of J head hot end. Plastic high temperature body and aluminium nozzle. The nozzle is relatively expensive to replace. I use it when I first started my Prusa I3. What happen is even with this body, YOU NEED A COOLING FAN. If not, your PLA might melt and solidify in it.

1) J-head , Aluminium nozzle , Plastic body

2) J-head with aluminium heat sink and brass nozzle.

3) Mk7Direct extruder

4) E3D Hotends.

Also , I had many sizes of nozzles. 0.2 to 0.5 And in the end, I prefer to use 0.4.

Let's talk about this type of J head hot end. Plastic high temperature body and aluminium nozzle. The nozzle is relatively expensive to replace. I use it when I first started my Prusa I3. What happen is even with this body, YOU NEED A COOLING FAN. If not, your PLA might melt and solidify in it.

This nozzle clot easily. residue stick to Aluminium and hence you will find that the flow gets smaller and smaller. Then after I cleared it, one might accidentally enlarge it. Because Aluminium is soft. How I clear the choke. Basically I heat it using bare flame of my cooking hob. Then I have to get a stiff wire or the right size drill bit to clear it. After clearing afew times, I got fedup with it. I changed to brass nozzle. And stop using J head. Now I have 2 sets of J head with 3 nozzles.

Next I bought a all metal J-head. I bought it cheap. probably less than 5 USD. I bought the heat sink , stem and nozzle separately. It works very well. Only thing is , YOU MUST HAVE A COOLING FAN. If you do not put a fan, the PLA filament will melt in the heat sink portion and solidify. then it will be hard to extrude. I machined My own heater block. Just for fun. Now I am still using this extruder/ hotend. The Brass nozzle is very important . It just don't choke. Ever since using this, I had never need to resort to barbeque my nozzle. I used a 0.4 mm nozzle.

Also I tried using direct extruder. Mk7 direct extruder with non contact heat sink but with fan.

This is a very simple but good extruder. Once I realised that maybe I do not need geared extruder, I put this into use. with indirect heat sink and fan. It works quite well but I still prefer the all metal j-head. I do get jam once in a while. But I think probably I did not set it well. I think this is simple and good. and importantly, nozzle must be brass.

lastly, I bought a E3D hotend. this is just a smaller version of all metal J-Head. so the result is comparable, but the size is smaller.

Additional cooling fan for the printed parts. I had a chance to use Felix 3D printer. I am very impressed by the printout. It is so simply built and printout is so good. I realised from Felix that you need another cooling fan for the printout. This is to make sure that the previous layer harden and make the structure more rigid. especially at slope. previous layer need to solidify or else some times, you see a big lump on the curve or slope at the side of it.

Saturday, 27 February 2016

How to Flash Dagu Mini Driver Boot loader

I believe flashing boot loader is nothing new. But the process may be abit tricky.

I used Arduino uno to program the Mini driver boot loader. Yes, you may be right. You need another arduino to program the one which you need a new bootloader. Common one is UNO. How to do it ?

1) connect you arduino Uno to PC using USB cable.

2) Select the correct port to connect. If you do not know, go to Control panel - > device manager -> ports to look for the port arduino Uno is connected. If you cannot find, that means Uno is not recognized in your system.

3) select the correct board to connect. In my case Arduino Uno ( not yet mini driver.)

4) In the arduino programmer, load the program called ArduinoISP. Upload it into arduino Uno.

5) Next connect your Uno to Dagu Mini driver.

6) Now in the arduino programmer, change the board to Arduino NG or older with ATmega 8.

You probably need to set programmer as USBasp.

7) Now goto Tools -> burnt boot loader.

8 ) Now you are done. You can now directly detect and upload the mini driver.

My Dagu mini driver setup.

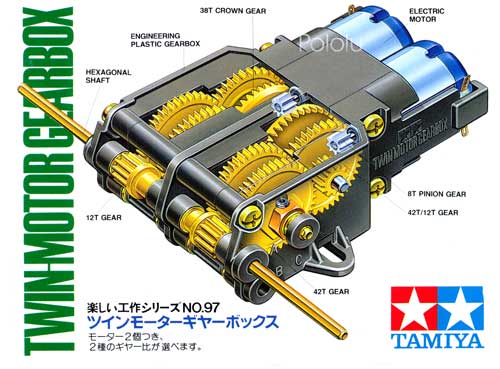

To set up a Bluetooth vehicle using Dagu mini driver and Bluetooth is so easy. Take a look at my configuration. You can use Tamiya base plate or cut your own aluminium base plate, or 3D print it. Also I am using a Tamiya twin gearbox motor to driver the car. You must be wondering why need gear box ? can't we just driver directly from the motor ? The answer is NO ! DC motor is running at a very high speed. so you car could be running too fast. and it consume too much current.

Dagu mini driver alternative programs.

For those who bought the Dagu robot, these are the alternative program to start with .

You can find more information at Dawn robotics blog .

Demo program for a car controlled by Dagu mini driver.

You can actually turn this program into a line tracker using IR sensor like TCRT5000,

or using sonar sensor to detect walls.

Hope this make a good start. If you need, change the motor speed as needed.

You can find more information at Dawn robotics blog .

Demo program for a car controlled by Dagu mini driver.

You can actually turn this program into a line tracker using IR sensor like TCRT5000,

or using sonar sensor to detect walls.

Hope this make a good start. If you need, change the motor speed as needed.

// Demo program for the Dagu Arduino Mini Driver. Uses dead reckoning // to try to drive a robot in a squareconst int LEFT_MOTOR_DIR_PIN = 7;const int LEFT_MOTOR_PWM_PIN = 9;const int RIGHT_MOTOR_DIR_PIN = 8;const int RIGHT_MOTOR_PWM_PIN = 10;const int DRIVE_FORWARD_TIME_MS = 1500;const int TURN_TIME_MS = 2000;//----------------------------------------------------------void setup(){ // Setup the pins pinMode( LEFT_MOTOR_DIR_PIN, OUTPUT ); pinMode( LEFT_MOTOR_PWM_PIN, OUTPUT ); pinMode( RIGHT_MOTOR_DIR_PIN, OUTPUT ); pinMode( RIGHT_MOTOR_PWM_PIN, OUTPUT );}//----------------------------------------------------------void loop(){ // Drive forwards at 100% // Try changing the maximum value to 100 if your car is running too fast. digitalWrite( LEFT_MOTOR_DIR_PIN, HIGH ); digitalWrite( RIGHT_MOTOR_DIR_PIN, HIGH ); analogWrite( LEFT_MOTOR_PWM_PIN, 255 ); analogWrite( RIGHT_MOTOR_PWM_PIN, 255 ); delay( DRIVE_FORWARD_TIME_MS ); // Turn right at 50%. Stop right motor on left motor. // you can change the value from 128 to lower. digitalWrite( LEFT_MOTOR_DIR_PIN, HIGH ); digitalWrite( RIGHT_MOTOR_DIR_PIN, LOW ); analogWrite( LEFT_MOTOR_PWM_PIN, 128 ); analogWrite( RIGHT_MOTOR_PWM_PIN, 128 ); delay( TURN_TIME_MS );With these, you can easily start you Dagu vehicle. You can check out Dawn robotics for their program with Bluetooth, which could be harder for some to understand. |

Dagu Mini driver with bluetooth

I bought a Dagu mini driver with bluetooth . I wanted to set up a easy remote control robot using any android phone. This arduino based driver fit what I wanted . I had 2 motor driver, 8 digital ports and 6 analog ports. And also 1 port ( of 4 pins ) for bluetooth module. This module is very useful for my purpose. 2 ports for motor, 8 ports which can be used for servo. 6 ports for any analog sensor.

There is also a switch on it. Built in diode to prevent plunging power supply in the wrong way.

Perfect !!!

At the PREFERENCE tab, once you click it, you can see

Next we change the visibility to invisible. We are only interested in some layout and we want to hide some buttons. Or else we will mispress the buttons. The options is a tick box.

There is also a switch on it. Built in diode to prevent plunging power supply in the wrong way.

Perfect !!!

I got into some problem initially . Arduino error :

avrdude: stk500_getsync(): not in sync: resp=0x0

I tried many ways to solve it, search through the web and discover nothing (to my surprise ).

So in the end I solved it by flashing the boot loader . How to flash the boot loader ? I shall do it another day.

First, for all Arduino, Bluetooth module must be remove before uploading.If in the event that you had damaged the bootloader, you can flash it. Remember take out the bluetooth first.

Next configure the bluetooth. Go to Play Store to find the app name Bluetooth Serial Controller .

Install it . Run it . Activate the Connect tab, and it shows you Bluetooth device that you can connect.

Choose HC-06 to connect. If this is the first time you connect, the password is 1234.

When it is connected the Bluetooth light will not flash anymore. Then , it is connected. Next configure your buttons. I has configure it to all these. You can hide, change functions, change text etc.I am preparing for a soccer playing Bluetooth remote control robot. So I have forward and reverse. left and right. Strike, defend and block. let us see how we do it.At the PREFERENCE tab, once you click it, you can see

options like Name, command visibility etc

Name , as it implies will show the name . Click on it, change the name of the buttons to what you want. You can see that I changed the buttons name for buttons 2,5,6,7,10, 4,8,12.

Next change the command for the buttons.

"0" = forward

"1" = backwards

"2 " = left

"3" = right.

"4" =stop.

You can add some more commands to buttons but you have to change the Arduino programs.

Next the arduino program that I used

// Modified by jack on Jan 2015

// Program for dagu mini controller.

//Standard PWM DC control

int M2 = 7; //ML Direction Control

int M1 = 8; //MR Direction Control

int E2 = 9; //ML Speed Control

int E1 = 10; //MR Speed Control

void stop(void) //Stop

{

digitalWrite(E1,LOW);

digitalWrite(E2,LOW);

}

void advance(char a,char b) //Move forward

{

analogWrite (E1,a); //PWM Speed Control

digitalWrite(M1,HIGH);

analogWrite (E2,b);

digitalWrite(M2,HIGH);

}

void back_off (char a,char b) //Move backward

{

analogWrite (E1,a);

digitalWrite(M1,LOW);

analogWrite (E2,b);

digitalWrite(M2,LOW);

}

void turn_L (char a,char b) //Turn Left

{

analogWrite (E1,a);

digitalWrite(M1,LOW);

analogWrite (E2,b);

digitalWrite(M2,HIGH);

}

void turn_R (char a,char b) //Turn Right

{

analogWrite (E1,a);

digitalWrite(M1,HIGH);

analogWrite (E2,b);

digitalWrite(M2,LOW);

}

void setup(void)

{

int i;

for(i=7;i<=10;i++)

pinMode(i, OUTPUT);

Serial.begin(9600);

Serial.println("-----LED Bluetooth Control-----");

Serial.println("++++++++++ Commands +++++++++++");

Serial.println("Press 0 to move forward.");

Serial.println("Press 1 to move backward.");

Serial.println("Press 2 to move left.");

Serial.println("Press 3 to move right.");

Serial.println("Press 4 to stop.");

Serial.println("nEnter Command: ");

}

void loop(void)

{

if(Serial.available()){

char val = Serial.read();

if(val != -1)

{

switch(val)

{

case '0'://Move Forward

advance (100,100); //move forward in max speed

break;

case '1'://Move Backward

back_off (100,100); //move back in max speed

break;

case '2'://Turn Left

turn_L (50,50);

break;

case '3'://Turn Right

turn_R (50,50);

break;

case 'z':

Serial.println(" Error ");

break;

case '4':

stop();

break;

}

}

else stop();

}

}

Subscribe to:

Comments (Atom)